Industry news|2022-01-21| admin

Planetary reducers are widely used in industrial automation, which involves a lot of professional knowledge, such as reducer selection, installation, maintenance and other related knowledge. These processes are also very important and need to be understood. Today, Shenzhen Weidong will introduce to you the selection, installation and maintenance of precision planetary reducer, hoping to bring you help.

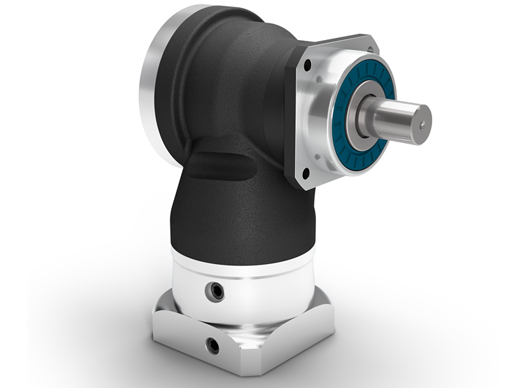

Among the reducers, planetary gear reducers are widely used in servo, stepping, DC and other transmission systems because of their small size, high transmission power, wide reduction scale, and high precision. Correct installation, use and maintenance of the reducer are an important part of ensuring the normal operation of mechanical equipment. Therefore, when installing the planetary reducer, be sure to carefully assemble and use it in accordance with the installation related matters of the reducer.

. Before installation, confirm whether the motor and the reducer are in good condition, and strictly check whether the dimensions of the parts connected with the motor and the reducer match. Here are the dimensions of the motor's positioning boss, the input shaft and the reducer groove and the matching public service.

Connect the motor and the reducer naturally. When connecting, it is necessary to ensure that the concentricity of the output shaft of the reducer and the input shaft of the motor is the same, and the outer flanges of the two are parallel. If the concentricity is not the same, it will cause the motor shaft to break or the gear of the reducer to wear.

Before the motor is connected to the reducer, the keyway of the motor shaft should be perpendicular to the tightening bolt. When installing, it is strictly forbidden to hit with a hammer to prevent the bearing or gear from being damaged by excessive axial force or radial force. Be sure to tighten the device bolts before tightening the tension bolts. The correct arrangement between the reducer and the mechanical equipment is similar to the correct arrangement between the reducer and the drive motor. The key is to ensure that the output shaft of the reducer and the shaft of the driven part have the same concentricity.

Load the planetary reducer with the recommended type and value of grease. The planetary reducer is lubricated with lubricating oil. For the planetary reducer with vertical installation, since the lubricating oil may not ensure the reliable smoothness of the upper bearing, other smoothing methods are used.

Before running, inject an appropriate amount of lubricating oil into the planetary reducer. It is generally equipped with oil filling holes and oil drain plugs. Therefore, when ordering the planetary reducer, it is necessary to install the device.

How to choose the fine servo planetary reducer. The selection of fine servo planetary reducer generally depends on the speed reduction ratio, installation method, output method, bearing capacity, output torque, output speed, return clearance, operating conditions, etc. The details are:

1. Selection of the speed ratio of the fine servo planetary reducer:

When selecting a planetary reducer, first of all, the reduction ratio should be specified. After confirming the reduction ratio, please multiply the additional torque of the servo motor you selected by the reduction ratio. In principle, the value obtained is smaller than the additional output torque of the nearby reducer provided by the product sample. , At the same time, the overload capacity of the drive motor and the working torque required in practice must also be considered. The required operating torque is less than twice the additional output torque.

Second, the selection of the size standard of the fine servo planetary reducer:

After meeting the above conditions, please choose a reducer with a smaller volume, and the cost of a small reducer is relatively low. If your space does not allow for a straight line connection of the motor reducer, you can also choose a corner reducer, which can turn the torque 90 degrees.

3. Selection of precision (return gap) of fine servo planetary reducer:

Next, consider the return clearance of the planetary reducer. The smaller the return clearance, the higher the accuracy and the higher the cost. Users can choose a series of reducers that meet their precision requirements.

4. Considering the service life of the fine servo planetary reducer:

Also consider lateral/radial forces and average life. The reducer with large lateral/radial force has high reliability in installation and use, and is not prone to problems. The actual life can be calculated according to the software provided by the manufacturer. Generally, the average lifespan far exceeds the lifespan of the equipped servo motor.

5. Other matters needing attention in the selection of fine servo planetary reducer:

After meeting the above objectives, you can select the reducer that matches your motor in terms of device size, shaft diameter and input flange according to the product catalog. Finally, you also need to consider the weight of the motor you are equipped with. A reducer is only allowed to be matched with a motor that is less than a certain weight. The motor is too heavy, and long-term operation will damage the output flange of the reducer.

In the reducer family, the fine servo planetary reducer is widely used in servo, stepping, DC and other transmission systems because of its small size, high transmission power, wide deceleration scale and high precision. On the premise of ensuring fine transmission, it is mainly used to reduce the speed to increase the torque and reduce the load/motor inertia ratio.

Several key technical parameters to measure the function of fine servo planetary reducer are: reduction ratio, average life, additional output torque, return clearance, full load power, noise, lateral/radial force and operating temperature.

①Reduction ratio: the ratio of output speed to input speed.

②Number of stages: The sun gear and its surrounding planetary gears form an independent reduction gear train. If there is only one gear train in the reducer, in order to obtain a larger reduction ratio, multi-stage transmission is required, and the reduction ratio ranges from 3 to 512.

③Average life: refers to the continuous operation time of the reducer when the speed is input under additional load.

Additional output torque: refers to the allowable output torque during long-term operation under additional load. The output torque is twice this value.

④Return clearance: When the output end is fixed, the input end is rotated clockwise and counterclockwise, so that when the output end generates a torque of ±2% of the extra torque, the input end of the reducer has a small angular displacement, and this angular displacement is the return clearance . The unit is "arc minutes".

⑤Smoothing method: The planetary reducer does not need to be smoothed during the entire application period.

⑥Full load power: refers to the transmission power of the reducer under the condition of heavy load. It is a key target to measure the reducer. The reducer with high full load power generates less heat and has good overall function.

⑦ Noise: The unit is decibel (dB) A. This value is measured when the input speed is 3000 rpm, no load, and a distance of one meter from the reducer.

⑧Operating temperature: refers to the temperature that the servo planetary reducer can allow under continuous operation and periodic operation.

The above is the relevant knowledge about the selection plan and installation and maintenance of the precision planetary reducer. The application of reducer is particularly extensive, of which installation and maintenance are an indispensable part. More relevant knowledge will be introduced to you in the future.