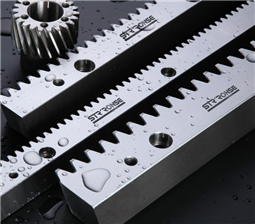

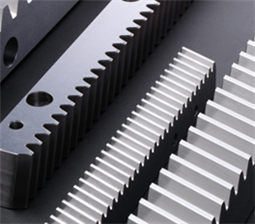

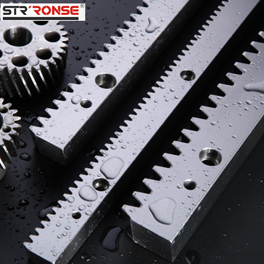

The fine-milled rack is divided into straight teeth and helical teeth. Guaranteed high tooth surface consistency. You can choose straight or helical teeth, module 2-5, length 500-1000mm.

Features of finely milled quenched and tempered rack:

1 The end design that can be extended can be connected/interchanged at will, and the stroke can be extended infinitely.

2 Accumulated error of precision milling level is 0.08mm≥1000.

3 With straight tooth/helical tooth profile, it is suitable for various usage conditions.

4 There are heat-treated/unheated types, and the same modulus can have multiple strengths.

5 Grinding the back and sides after tempering

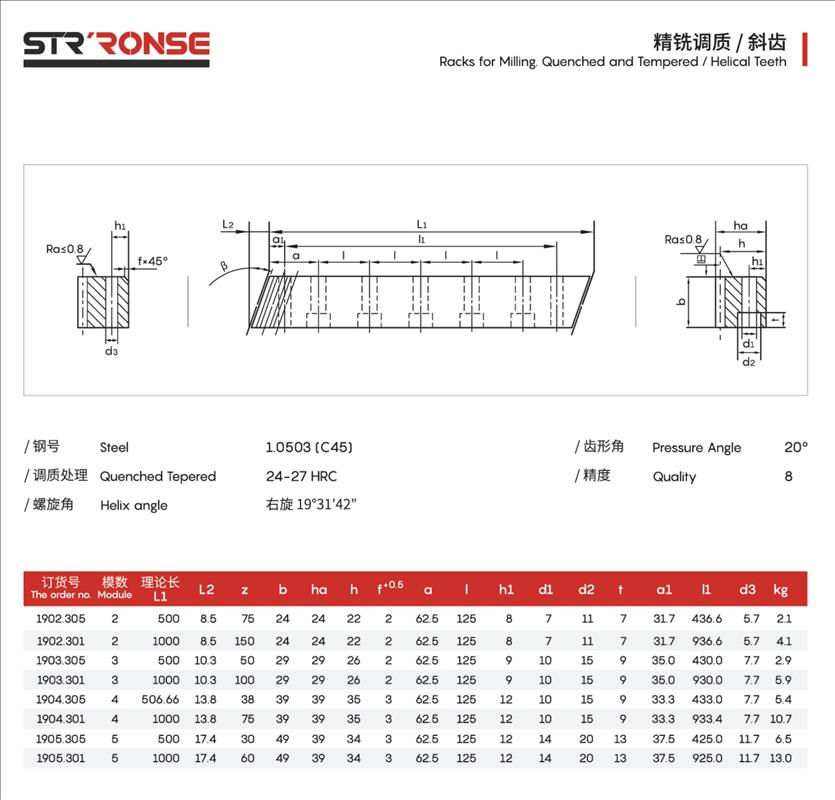

| Order no. | Module | L1 | L2 | z | b | ha | h | f+0.5 | a | l | h1 | d1 | d2 | t | a1 | l1 | d3 | kg |

| 1902.305 | 2 | 500 | 8.5 | 75 | 24 | 24 | 22 | 2 | 62.5 | 125 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 | 2.1 |

| 1902.301 | 2 | 1000 | 8.5 | 150 | 24 | 24 | 22 | 2 | 62.5 | 125 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 4.1 |

| 1903.305 | 3 | 500 | 10.3 | 50 | 29 | 29 | 26 | 2 | 62.5 | 125 | 9 | 10 | 15 | 9 | 35 | 430 | 7.7 | 2.9 |

| 1903.301 | 3 | 1000 | 10.3 | 100 | 29 | 29 | 26 | 2 | 62.5 | 125 | 9 | 10 | 15 |

9 |

35 | 930 | 7.7 | 5.9 |

| 1904.305 | 4 | 506.66 | 13.8 | 38 | 39 | 39 | 35 | 3 | 62.5 | 125 | 12 | 10 | 15 | 9 | 33.3 | 433 | 7.7 | 5.4 |

| 1904.301 | 4 | 1000 | 13.8 | 75 | 39 | 39 | 35 | 3 | 62.5 | 125 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 | 10.7 |

| 1905.305 | 5 | 500 | 17.4 | 30 | 49 | 39 | 34 | 3 | 62.5 | 125 | 12 | 14 | 20 | 13 | 37.5 | 425 | 11.7 | 6.5 |

| 1905.301 | 5 | 1000 | 17.4 | 60 | 49 | 39 | 34 | 3 | 62.5 | 125 | 12 | 14 | 20 | 13 | 37.5 | 925 | 11.7 | 13 |

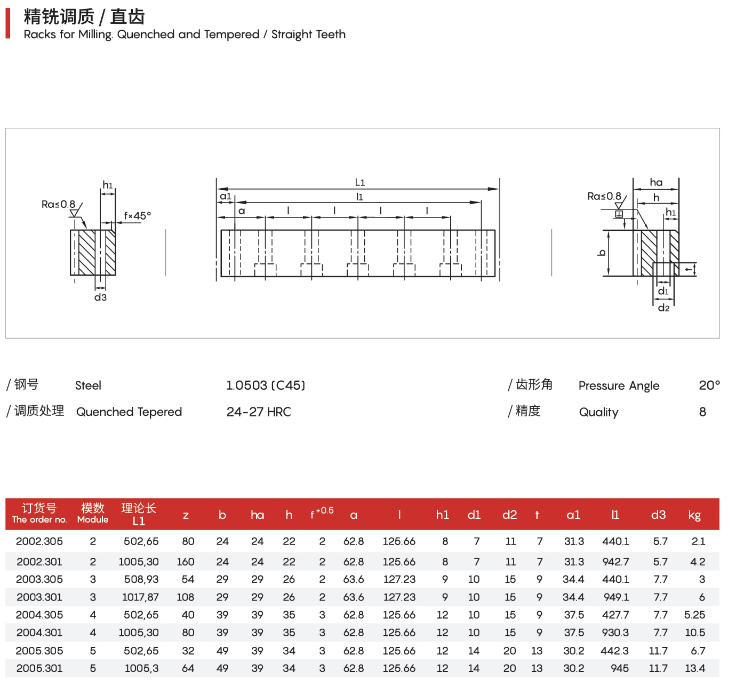

| Order on. | Module | L1 | z | b | ha | h | f+0.5 | a | l | h1 | d1 | d2 | t | a1 | l1 | d3 | kg |

| 2002.305 | 2 | 502.65 | 80 | 24 | 24 | 22 | 2 | 62.8 | 125.66 | 8 | 7 | 11 | 7 | 31.3 | 440.1 | 5.7 | 2.1 |

| 2002.301 | 2 | 1005.3 | 160 | 24 | 24 | 22 | 2 | 62.8 | 125.66 | 8 | 7 | 11 | 7 | 31.3 | 942.7 | 5.7 | 4.2 |

| 2003.305 | 3 | 508.93 | 54 | 29 | 29 | 26 | 2 | 63.6 | 127.23 | 9 | 10 | 15 | 9 | 34.4 | 440.1 | 7.7 | 3 |

| 2003.301 | 3 | 1017.87 | 108 | 29 | 29 | 26 | 2 | 63.6 | 127.23 | 9 | 10 | 15 |

9 |

34.4 | 949.1 | 7.7 | 6 |

| 2004.305 | 4 | 502.65 | 40 | 39 | 39 | 35 | 3 | 62.8 | 125.66 | 12 | 10 | 15 | 9 | 37.5 | 427.7 | 7.7 | 5.25 |

| 2004.301 | 4 | 1005.3 | 80 | 39 | 39 | 35 | 3 | 62.8 | 125.66 | 12 | 10 | 15 | 9 | 37.5 | 930.3 | 7.7 | 10.5 |

| 2005.305 | 5 | 502.65 | 32 | 49 | 39 | 34 | 3 | 62.8 | 125.66 | 12 | 14 | 20 | 13 | 30.2 | 442.3 | 11.7 | 6.7 |

| 2005.301 | 5 | 1005.3 | 64 | 49 | 39 | 34 | 3 | 62.8 | 125.66 | 12 | 14 | 20 | 13 | 30.2 | 945 | 11.7 | 13.4 |